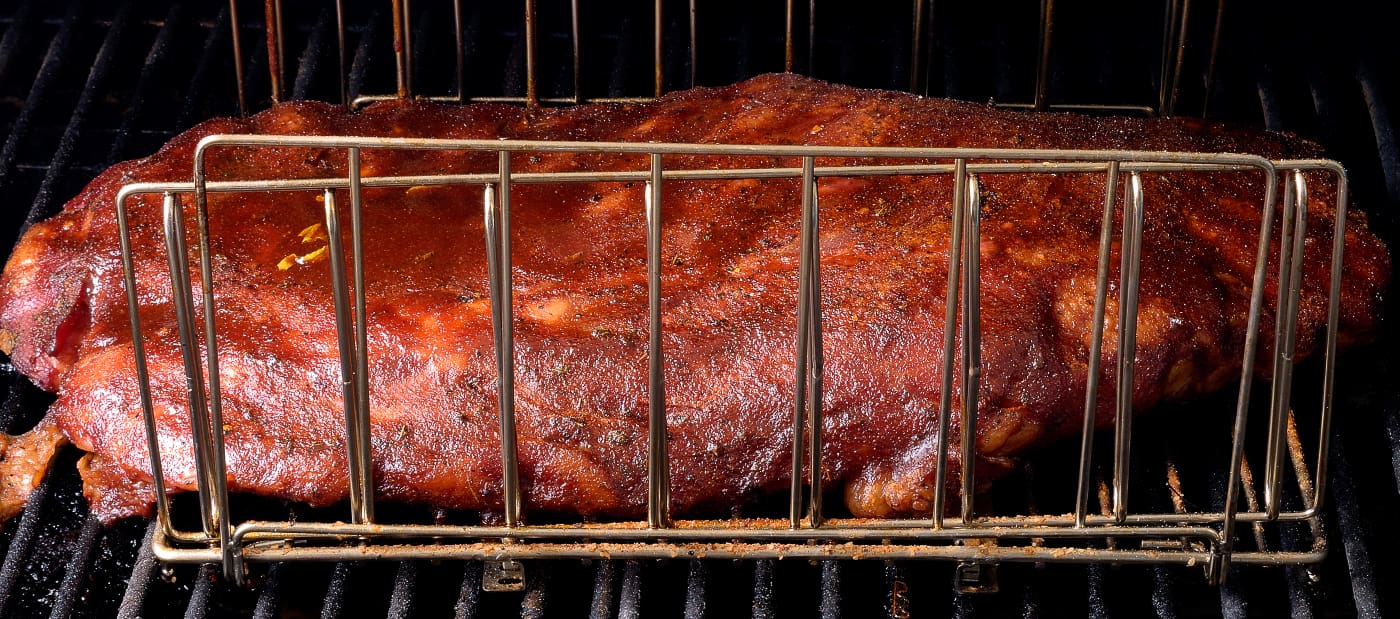

Above: a full side of pork spare ribs in a Lipavi C20 container, with an L20 stainless steel rack and Lipavi C20L-UNIR lid.

Actual prep time, 1 hour

Serves 1 person per lb./450 g unless you’re in Texas.

Level of difficulty 2.5

No, you can’t turn an igloo into an aquarium

Sous vide novices use all manner of containers as they familiarize themselves with the technology. After some experimentation and practice, at least one thing becomes perfectly clear–literally. One should be able to see what’s transpiring in the container without lifting the lid. Sometimes bags leak unexpectedly; it’s better to find out as soon as possible. Sometimes immersion circulators fail with no warning or indication–a transparent container makes obvious the fact that the water has stopped circulating. Lids not only prevent the escape of heat energy, they should seal against the water’s surface to prevent packages from floating. Lipavi gear has all of these contingencies covered.

It is not enough to sink

Once the packages are fully submerged during processing, racks are used to prevent the packages from coming in contact with each other or the surface of the container. This flow is important for safe, consistent results. Racks need to be non-reactive and water proof. The temperatures utilized are low enough that heat tolerance is not usually an issue–dishwasher temperatures are higher than most sous vide parameters. Lipavi stainless steel racks are oven/smoker proof, stain proof and rust proof, expanding their applicability to roasting and hot smoking.

Procedure

In the first slide below, the pork spare ribs have been removed from their packaging. Sizes range upward from 3lbs./2.2 Kg to as high as 8 lbs./3.6 Kg.

Market packaging is designed to withstand refrigeration and a certain amount of friction, but it is not intended or rated for sous vide processing.

The rack can be reduced to fit into dedicated bags without affecting time or temperature parameters, because sous vide is not as weight dependent as it is thickness dependent. Once the rack(s) are vacuum packaged in dedicated sous vide pouches, the sous vide process can begin.

Temperatures

The higher the temperature applied, the shorter the tenderization interval will be. The lower the temperature applied, the less moisture will be lost. 140 F/60 C is a sort of “base line” for sous vide, but pork can be safely processed at temperatures as low as 132 F/56 C as long as pasteurization requirements are met. Once a processing temperature has been selected, time will determine the eventual texture of the protein. Tenderness is subjective and its perception varies from person to person.

A clock cannot be used to measure tenderness–only the practitioner can do that. To learn how to measure tenderness without (or with) breaking the seal on the package, visit HERE.

At 140 F/60 C, pork spare ribs usually take approximately 24 hours.

At 132 F/56 C there will be considerably less moisture release, but the process will take closer to 30 hours.

Baby back ribs usually require somewhat less time at 140 F/60 C–18 hours in most cases, with an incremental increase when the lower temperature is applied.

Pork butts are higher in collagen, so they may take 30 hours or even more, depending on the results desired. Pulled pork requires temperatures as high as 165 F/74 C to achieve the desired result.

Pork loins and chops all have their own temperature/time requirements and so forth. Visit HERE to see our tried and true recipes for all the various cuts of pork.

What to do after the initial processing

Cold shocking is just as important as sous vide pasteurization itself. After processing, all food should either be finished and served or shocked cold with iced water to 70 F/21 C BEFORE being staged into a 40 F/4 C refrigerator–whether it was prepared via sous vide or not. Home refrigerators/freezers are not designed to safely cool hot food. Perishable products in the vicinity of the hot packages can also be temperature damaged by this exposure.

The hot water can be siphoned out of the container and replaced with iced tap water. The loaded racks can be removed from the container and fully submerged in cold water in a kitchen sink. Alternatively, the individual packages can be removed from the rack and submerged in a container/sink with cold water. For most items, cooling to 70 F/21 C by this method will take about 30 minutes. After the items have been submerged for 15 minutes, use a probe or infrared thermometer to measure the temperature of the water. This will give you an idea of your progress. If the water is over 80 F/27 C after 30 minutes, drain the sink and refill. This is usually only necessary with larger cuts of meat (over 5 lbs./2.25 Kg). Results may vary.

Storage

Once your packages have achieved 70 F/21 C, they can be refrigerated and held at 40 F/4 C for up to two weeks without any significant loss of quality or wholesomeness–much like a sealed carton of pasteurized milk. The rack, with the packages still in it, can be staged into a normal sized refrigerator. Whether you transfer the rack into the refrigerator or not, care must be taken to allow the flow of cold air around the packages–do not crowd the refrigerator.

Using racks for hot smoking

Sous vide proteins should start their journey to smoked perfection at 40 F/4 C or thereabouts. This prevents the meat from exceeding its original target temperature. It also maximizes the development of smoke flavor. On the day of service, submerge the packages in hot tap water to dissolve the gel that forms around the proteins. Always harvest the juices in the bag–if there are any. The lower the temperature applied, the less juice will be released. This Sous Jus™ can be clarified and used in almost any savory recipe that calls for stock or water.

There is no need to “rub” the ribs in order to make your seasonings stick. For an easy way to do this, refer to the method explained in detail HERE. Load the ribs into the rack and transfer to the smoker. A sheet pan is useful for transporting the racks from the kitchen to the smoker. Some practitioners put the sheet pan and rack directly in the smoker, some do not–choose whichever method is more convenient for you. Some enthusiasts insist that the sheet pan will reduce the amount of smoke imparted to the meat. My experience is that once an item is inside a smoker, there is no way to prevent the flavor and smell of smoke from attaching itself to anything and everything.

Low and Slow is the Way to Go

The temperatures used in hot smoking usually start around 180 F/82 C–pellet grills can achieve this fairly accurately. Air is an inefficient conductor of heat energy. Because of this and the effect of evaporative cooling, the contents of a smoker (or oven) will never actually achieve the temperature of the setting. The lower the temperature used, the more smoke flavor will be imparted to the meat. Smoke flavoring does not actually penetrate the complex protein matrix of meat, but it will cling to a moist surface–this effect justifies pitmasters’ practice of “mopping” their meat. This controversial subject is discussed in detail HERE.

Depending on the temperatures applied and the individual smoker, it can take anywhere from 90 minutes to 6 hours to achieve the desired appearance, texture and a minimum internal temperature of at least 140 F/60 C.

To Baste or NOT to Baste

It is doubtful that a consensus will ever be achieved as to whether bastes/sauces should be applied during the smoking process. Each American region/state/province/county defends their version vehemently, commonly insisting that their particular interpretation is the only “authentic” one. Embracing diversity in most things, I have managed to avoid settling on one viewpoint or another. When people ask me which style I prefer, I tell them that I have never met a style of BBQ that I did not like. If we cared as much about each other as we do about whether our ribs’ surfaces were wet or dry, well, what a world it would be!

Once all requirements have been met, turn off the smoker before opening the door if possible. This minimizes your exposure to toxic fumes. In a few moments, the handles on the ends of the Lipavi racks will have cooled somewhat and are much easier to handle; always use a hot pad, regardless.

In this case, we applied Sous Vide Barbecue Baste 45 minutes before removing from the smoker. This is a robust and zesty companion for steaks, ribs, chicken, and many other things. It is an excellent alternative dip for French Fries and Onion Rings.

Serving your Sous-B-Q Pork

Stage the rack onto a sheet pan for safe and convenient transport. This rack of spare ribs started at 7 lbs./3.2 Kg. Final weight was 6 lbs./2.7 Kg–approximately 15% shrinkage.

The juices were clarified according to the process explained HERE, after which there was a meager 1 cup/225 ml of moisture release. This minimal amount of shrinkage is unachievable by any other method of cooking, even when you consider the subsequent amount of time in the smoker.

It’s a beautiful thing.

Why is it pink? The exposure to carbon monoxide (CO) and nitric oxide (NO) cause a chemical reaction that prevents myoglobin from oxidizing. This phenomenon is also responsible for the “smoke ring” present in some BBQ items. BTW, myoglobin is not blood. Myoglobin is an oxygen transporting protein present in muscles (not in blood vessels).

Norm